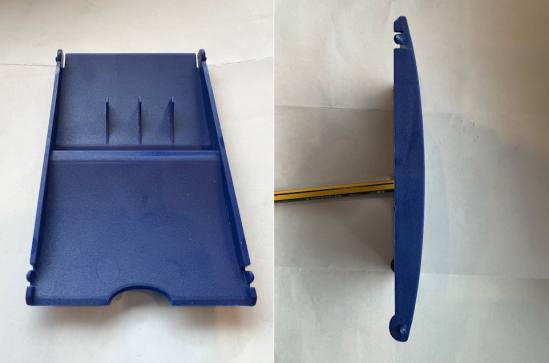

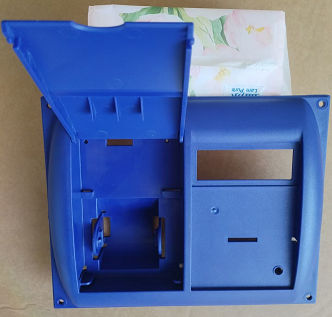

Plastic part: TST-PC cover for refrigeration control system

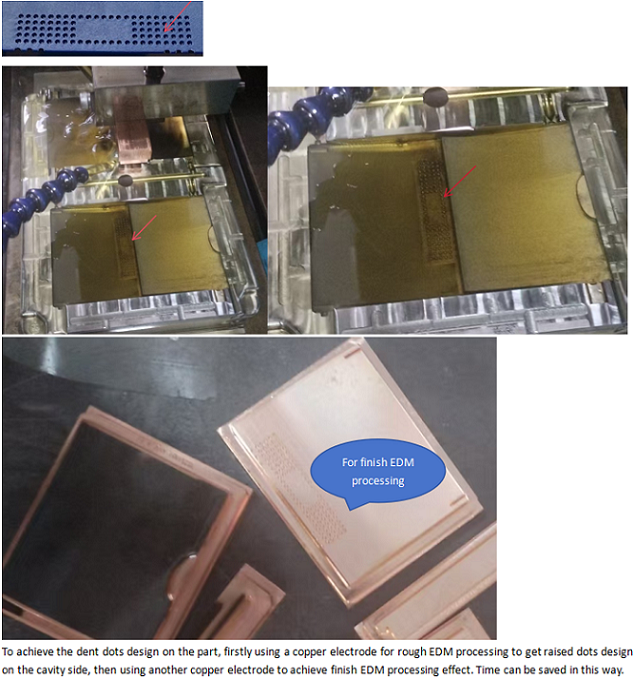

W/ texture(chemical etching in mold) on part surface

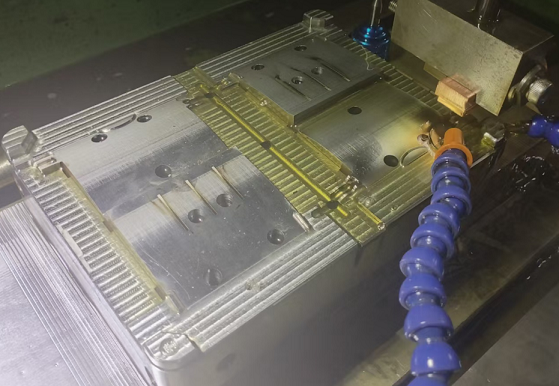

*Chemical etching rather than EDM processing due to bigger grains of texture

Requirement: accurate color and durability

In plastic raw material: ABS(MABS)

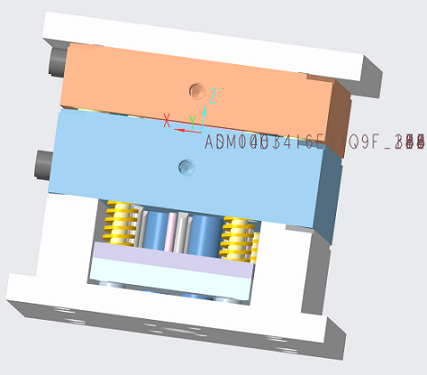

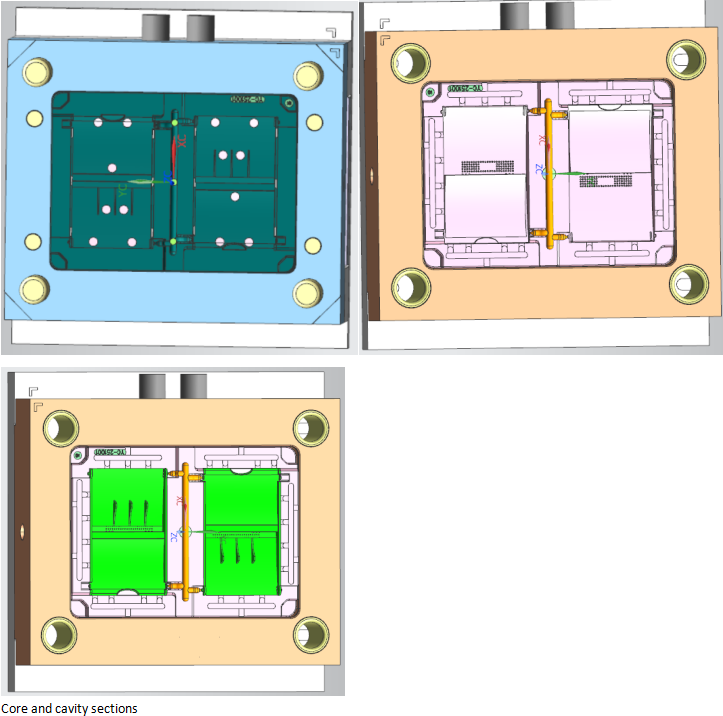

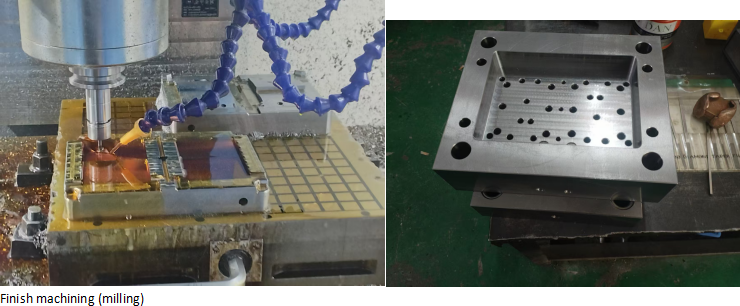

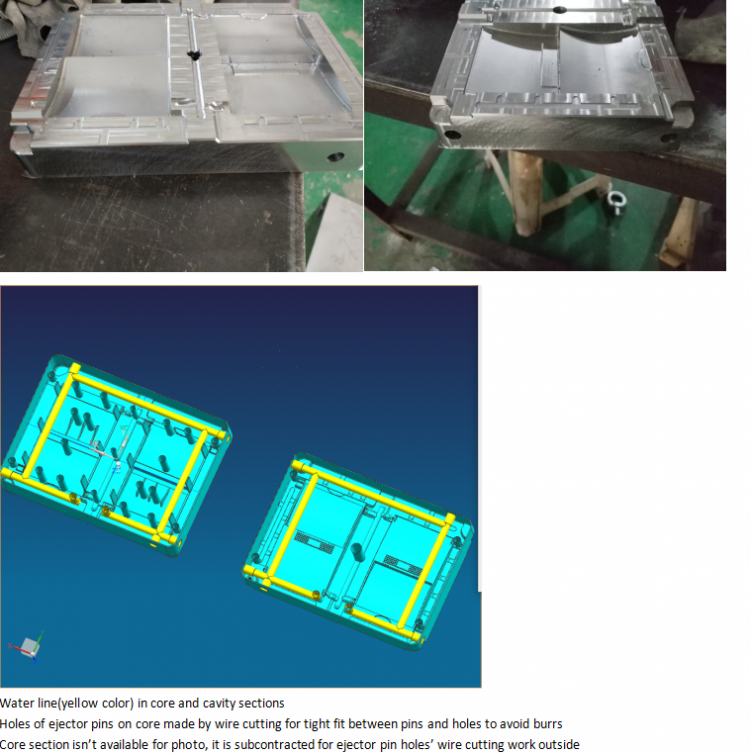

Plastic mold: 1x2 cavities; common gate type, w/ same gate position at 2 small column ends like part sample; 2-plate type

Mold base P20 steel; Mold core 718H steel

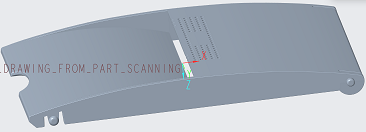

STP format drawing for part

STP format drawing for part STP format mold drawing

STP format mold drawing

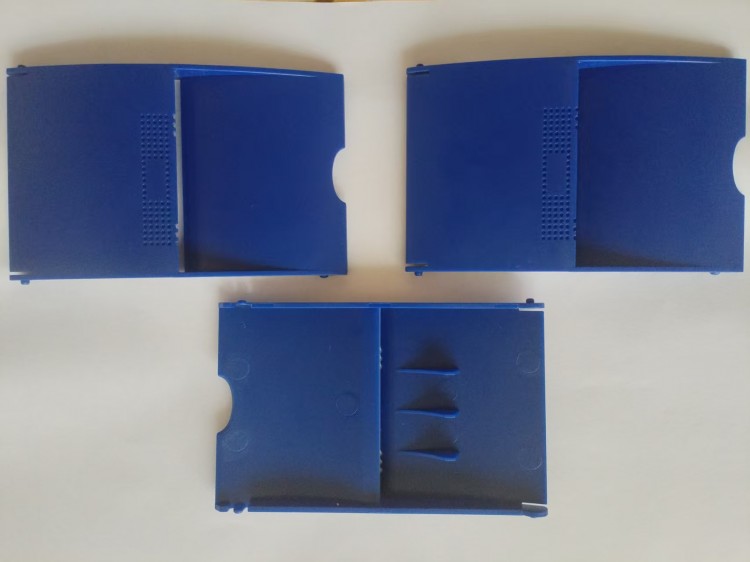

Parts from mold test before polish and texture making(visual color difference from shooting environment)

*1st batch cover samples was with EDM texture for checking texture effect

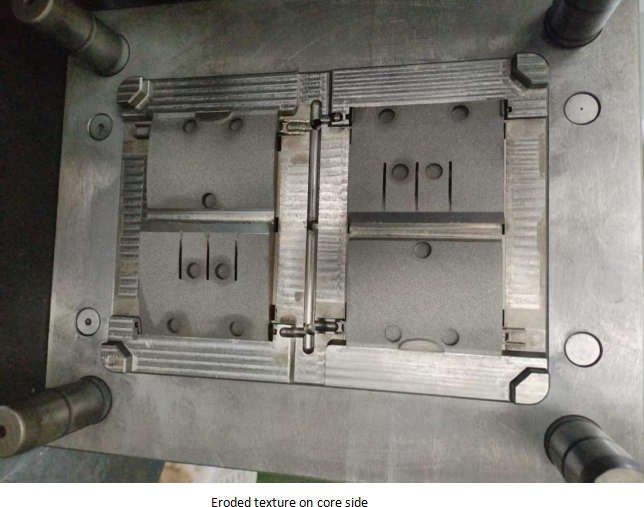

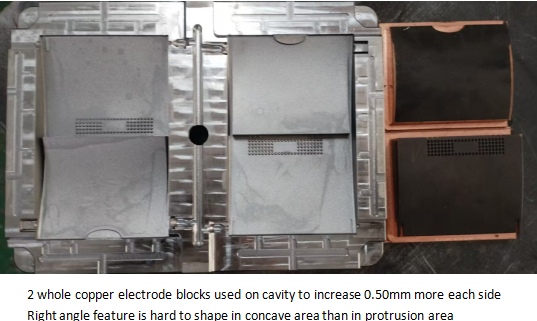

Core side after modification

Core side after modification

To get tight assembly of cover and enclosure, modify the mold at following positions:

- Balls(i.e. small columns) which connects the enclosure serves as hinge function, reduced plasic in crosssection by around 0.14 ~ 0.15mm (Processing: welding firstly, EDM machining secondly)

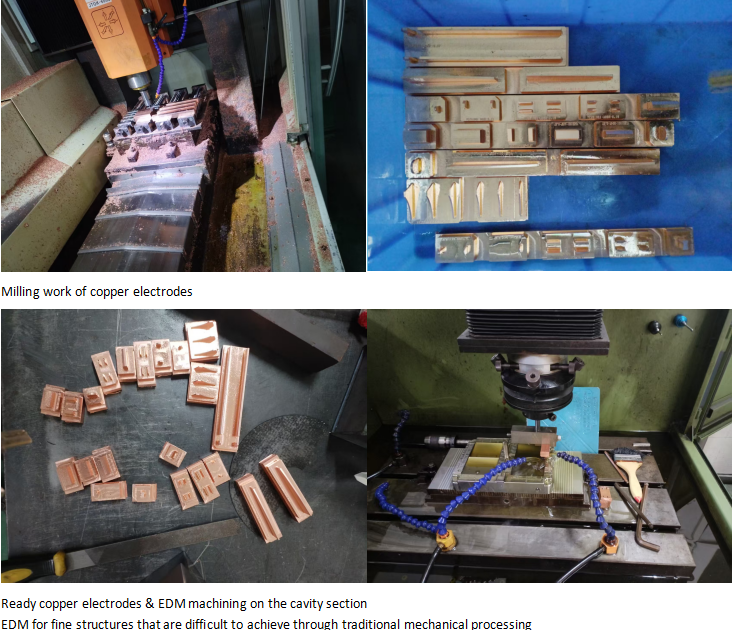

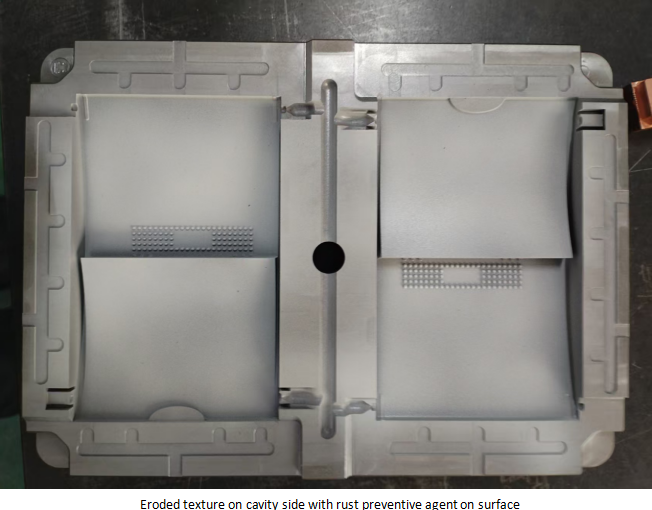

-Increase plastic 0.50mm at both sides at width direction(hinge side): Use new-made copper electrode bar for EDM machining to get 0.50mm increase each side on core(0.50mm increased at both core and cavitty to avoid 'step(mold line)' appears at the side wall bottom), with old texture kept. While use new whole copper electrode blocks for EDM machining on cavity to get 0.50mm width increase each side, the right angle corners* of cover can be kept, without 'Radius' happened there. The eroded texture is re-made by subcontraction.

After modifications, at each each hinge side there is 0.35mm gap beween cover and enclosure when the cover is closed, cover can open and close freely.

Assembly of cover and enclosure:

With one hand hold the enclosure, another hand with the cover in vertical way, put the the ball (small column) of one side into the one side slot of enclosure, meanwhile push the side of another ball(small column) a little bit to let this one come into the another slot of enclosure. it doesn't matter there is a bit tight feeling after their assembly, with some more open and close operations, the operation will be felt properly, just like one person's new shoes.