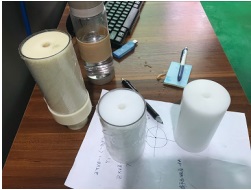

*CNC turned parts

*Above pictures taken on 19th Mar. 2018 from 1st time samples

*In POM

*A.Pulley: Pulley: Dia.15mm Height 15.5mm

28th Mar., 2018: add M3 thread on side hole

B.Left/right-axis: Dia.70mm height 17.6mm/15.6mm

28th Mar., 2018 right axis:change 6 holes' size from Dia.1mm to 1.5mm, length of these holes from 10mm to 8mm

left axis: same change as axis-right and change Dia. of groove from 2mm to 3mm

C.Tube: Length 118mm Dia.70mm Dia.66mm

In 'TARFLON' Transparent PC IR2200

28th Mar., 2018: change size of 12 holes from Dia. 3.2mm to 2.2mm

*Tube part sample is processed from Dia.70mm PVC tube material

*Picture at right side shows the sub-assembly situation

Customer comments: " ...we tested the shaker. Thank you very much for the excellent work..." 23th Mar. 2018

*Left: With concern PVC tube becoming brittle over time, replace it by PC tube

Polycarbonate(TARFLON IR2200) D70*2mm tube

(22nd Apr. 2018)

Right: ABS fixture with PC tube on, ready for CNC turning process

Above photo: 10th May, 2018

Customers' comment:

"I checked all parts except the pulley, they look good!, .....we are still waiting for motor delivery. so we can not check pulley and the motor mount on the metal part yet..." -29th May, 2018

"thank you very much for your efforts. ..." -31st May, 2018