*Part name: Extruded aluminum profile

*Material: GB-6063-T5 (AL -6063-T5) aluminum alloy

- 6063 aluminum alloy chemical ingredients: Cu 0.1%, Si 0.2%-0.6%,Fe 0.4%,Mn 0.1%,Mg 0.45%-0.9%,Zn 0.1%,Cr 0.1%;Ti 0.1%,Al 97.6%-98.45%

- T5 hot treatment method, higher tensile strength and hardness, more stable mechanical properties

6063-T5,this grade is often used, price is moderate, the oxidation effect is also acceptable.

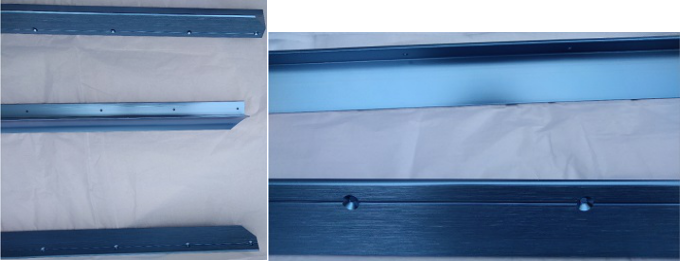

*Surface treatment: common anodized blue color, 5~8µ thickness

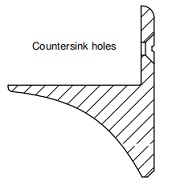

16 countersunk holes, 45° chamfer at each end

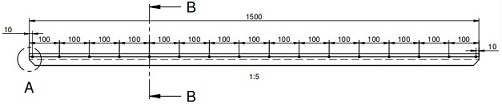

1.5 meters length extruded aluminum profile

*Application: attached into small boat hull (pilot project)

*Manufacture process: Material extrusion - Cutting - Anodizing blue - inspection for packing

Machining workshop scenes(Morning 15th Sept., 2018)

*1st time tooling trial : 17th Oct., 2018 *Good profile from tooling trial 20th oct., 2018

*Plane type(w/ bearing land feature and w/o flow guide) extrusion tooling;

*Vickers-hardness of profile: 10~12;

*brush treatment suggested to be on side has countersunk holes

*Tolerance for total length: +/- 0.3mm

Good finished aluminum profile samples (26th Oct., 2018):