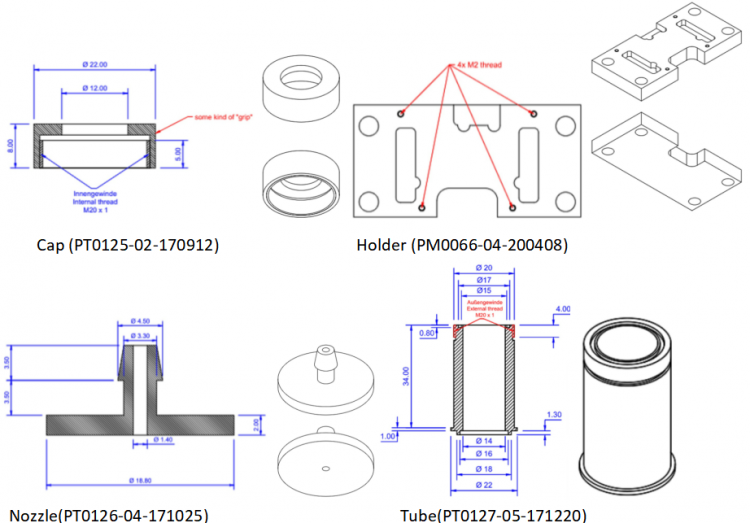

*Parts for mobilab series

*In POM material

*Tube part in white and blue colors separately in half of quantity

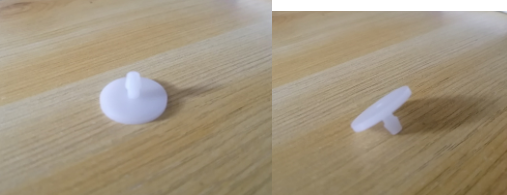

Nozzle/Cap/Holder/Front parts in white color

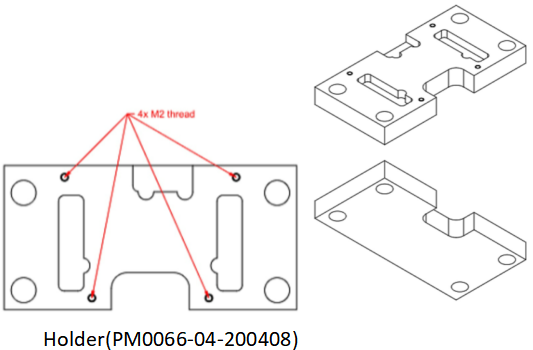

Holder part in blue color

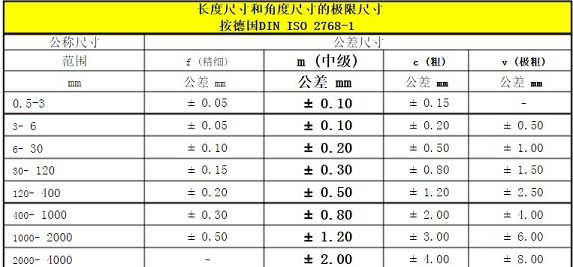

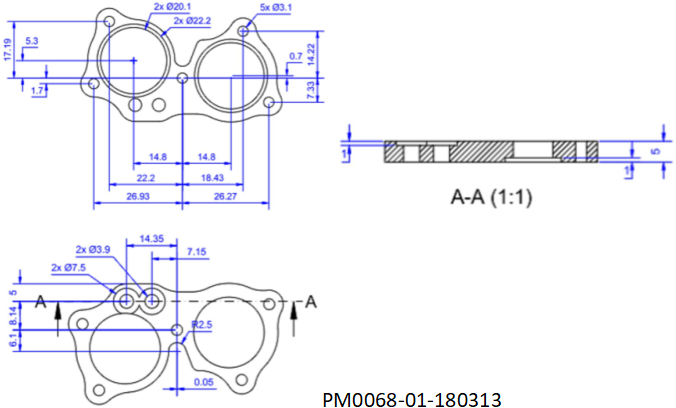

*Tolerance execution standard DIN ISO 2768-1 (fine)

*Use approx. 0.3° chamfer to remove burrs

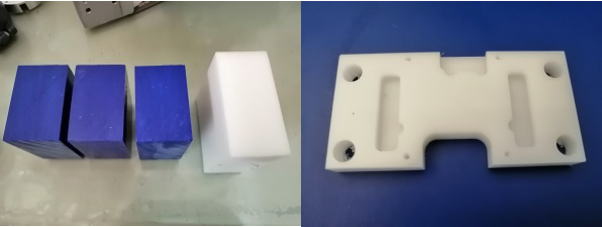

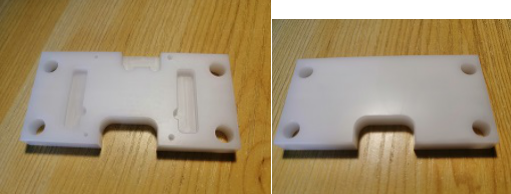

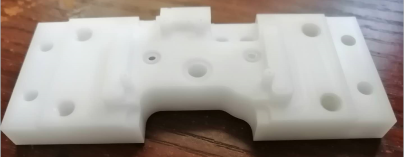

POM material & Semi-finished part -Holder (still with machining residue and an obvious cutting stripe at the back)

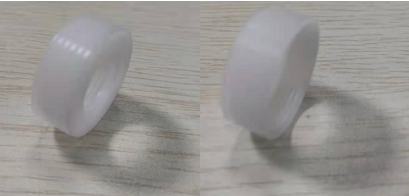

Finished part -Fastener (made by CNC milling processing)

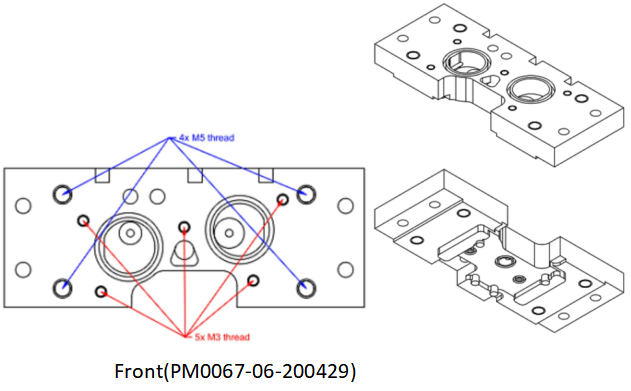

*For Front part, materials are processed ready in suitable size for further machining work -milling

The rest 3 kinds of parts -Tube/Nozzle/Cap are made ready by CNC turning(lathe) processing (June. 2nd, 2020)

*MobiLab Cap v2: surrounding side surface with turning texture, i.e. slots with width 0.8 and depth 0.3~0.5

*MobiLab Cap v2: surrounding side surface with turning texture, i.e. slots with width 0.8 and depth 0.3~0.5

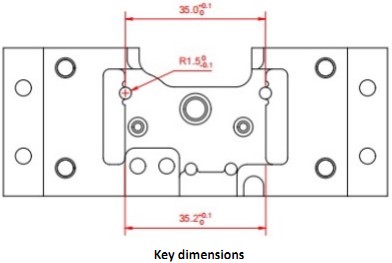

*Semi-finished part(Front),

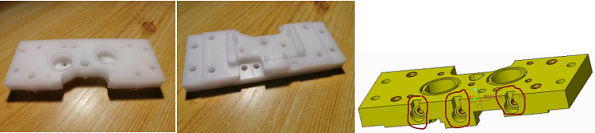

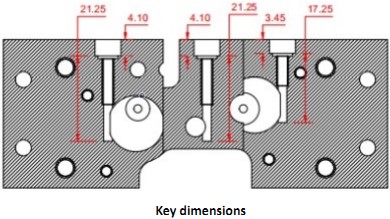

Firstly, with milling cutter and drill bits works one by one in turn and actions following the setted program, the features on each of 2 biggest surfaces are made by a dozen of different kinds of milling cutter and drill bit installed in CNC mahcine in one machining cycle.

Making of 3pcs M3 threaded blind holes and their slots(red circled) are left as last machining procedure from the side surface, then the right angles of slots can be formed well by milling cutter, without radius occured at the corner.

*3rd time front part

- Warping along width and Longitudinal directions are improved furtherly till no warping

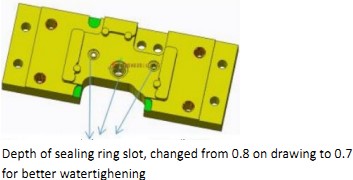

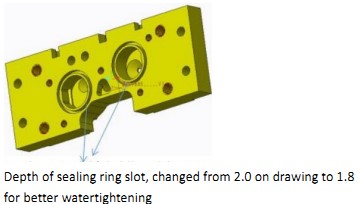

- Depth changes of sealing ring slot

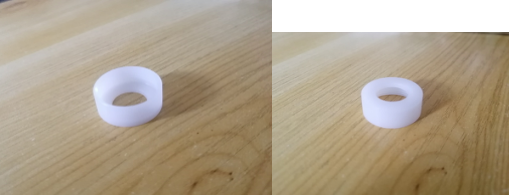

Normally, before complete assembly, one-third height of the sealing ring should be exposed naturally ourside of it's slot.

(*in case no slot to fix the sealing ring, the cross-section of the ring is square.)

a. Sealing ring for big slot: Inside diameter 5mm, cross-section diameter 1mm (-the inner diameter of the sealing ring is 2.5mm, whereas the inner diameter of the slots is 3mm. So the O-ring is stretched, thus it has a reduced cross-section. changing the width potentially results in loose sealing, width 0.9mm kept same as drawing.)

Sealing ring for 2 small slots: Inside diameter 2.5mm, cross-section diameter 1mm

b.The cross-section of the sealing ring is circular with 1mm diameter(0.79 square milimeter), the below slot for the sealing ring is indeed 1.2*2.0, but the tube part is inserted 1.3mm deep, the remaining cross-section of the slot is 1.2*0.7( 0.84 square milimeter)

-Thread holes: holes are made by CNC milling machine, threads are drilled later by bench-type drilling machine controlled by hands.

-POM block material is from the source often designated by bigger manufacturers

-Usually, part with such design is made of aluminum, warping doesn't happen. POM material is chosen due to the part itself is required to be non-conductive, several times sample making or much slower making process is needed to abserve and accumulate experiences.

Customer comments to final 'Front part': They finally worked as expected.