*Arrow indication: laser beam cutting starting and ending point

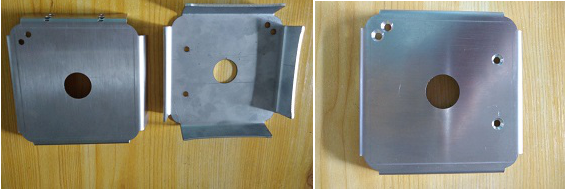

Above sample picture taken on 3rd Mar., 2018

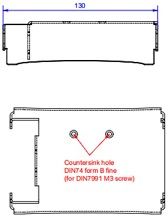

Application: for NPK shaker project

Material: 1.5mm thickness SUS304 stainless steel

Part size: 129.8x89.05x36.32mm

Production tolerance: +/-0.1mm for laser cut, +/-0.5mm after bending work

*28th Mar., 2018 change 8 holes to M3 threads ones, change 2 holes to countersink for M3 screw and change their position

*MobiLabl_shaker_bottom part v5 (18th Mar., 2019):

a.for better look, slightly larger countersink holes are used to suit DIN7991 M3 screw head

b.lenth is increased to correct the problem of stand part is bending naturally and protruding bottom part on the lower side

c.added symmetry on drawings and avoided unnecessarily complex dimensions

Above photoes for mobilab balance base taken on 5th Apr. 2018

*4 countersink holes for M3 screw

*Round holes are CNC laser cutted with precise size, no need to check this size after part is made.

*There is slight tolerance for actual bending angle, which result in 0.34mm increased distance between two opposite bending edge(83.72 to 84.06mm)

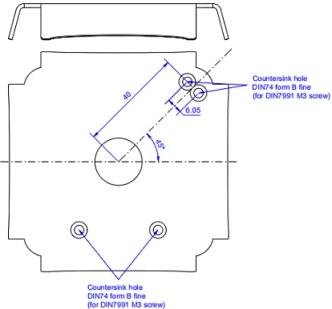

*28th Mar., 2018 change 8 holes to M3 threads ones, change 2 holes to countersink for M3 screw and change their position

*MobiLabl_scale_bottom part v5 (18th Mar., 2019):

a.changed middle hole dia. from 16mm to 18mm

b.screw heads were protruding surface of old countersink holes, for better look, slightly larger countersink holes are used to suit DIN7991 M3 screw head

c.distance between centers of countersink holes and that of middle hole is increased a bit to 40mm, it is crucial to functionality of device.

In case your project need metal bending part, pls feel free to contact us, welcome business cooperation, careful and strict workmanship ensure good precise quality part.