*µMETOS TRH-Console V1.0 in 2mm stainless steel 304# w/ 3pcs M3 thread holes

*ECOD3-console WS-GR V1.3 Parts A, B and C in 1mm stainless steel 304#

*ECOD3-console V13 part in 1.5mm stainless steel 304#

*PI-USD-Holder V1.0 part in 2mm stainless steel 304# w/ 1pc Pg7 and 3pcs M4 thread holes(Dia.4.5mm)

*Made mainly by laser cutting and bending processes, other auxiliary processes are important too.

1)ecod3_console_TrH_v14 4th Dec.2019 in 2mm stainless steel 304# sheet w/ 3pcs M3 thread holes

2)ecod3_console_WS_v14 A & B parts 4th Dec.2019 in 1mm stainless steel 304# sheet

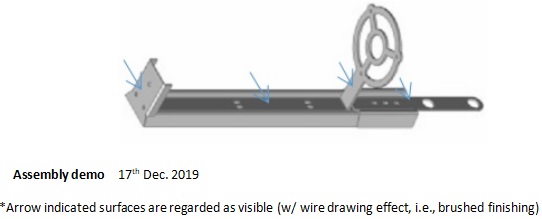

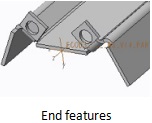

19th Dec. 2019 Part A - to get precise laser cutting and bending angle as 3D drawing v14 shows(the part become smaller in overall size proportion than before), especially features at one end of part, 2 more workdays are needed.

3)ecod3_console_GR_v14 4th Dec. 2019 (updated from old C part of ECOD3-console WS-GR V1.3) in 1mm stainless steel 304# sheet

4)ecod3_console_main_v14 4th Dec. 2019 in 1.5mm stainless steel 304# sheet

5)PI-USD-Holder v1.1 4th Dec. 2019 w/ 1pc PG7 thread hole, only 3pcs holes with 2.25 Radius needed instead of M4 thread hole

*Secondary processing for PI-USD-Holder v1.1 part order -13th Dec. 2019

a.)After pg7 thread hole is drilled, burrs around the hole is removed by bigger drill bit of milling machine