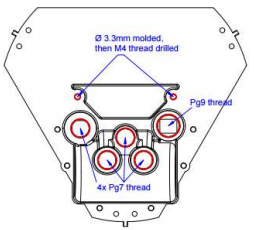

1) Pg7 thread hole at old crown position

2.

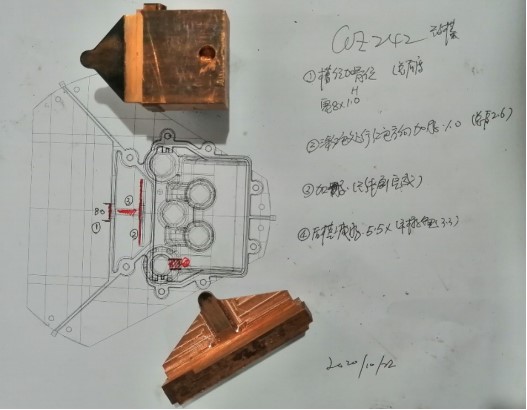

- Add plastic wall( w/ height as possible as 14~14.5) between 2pcs plastic walls which hold ¢2.0 steel rod

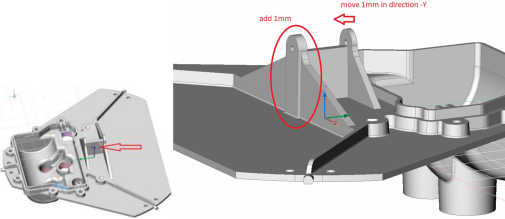

-Add 1mm thickness narrow strip on 1 of walls supporting dia.2.0 pin

-Add 1mm thickness in the side( direction –Y) of another of walls supporting dia 2.0 pin

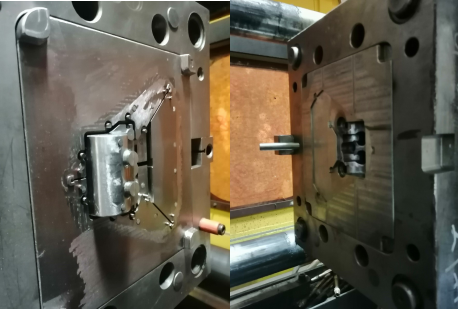

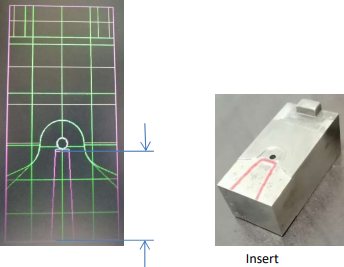

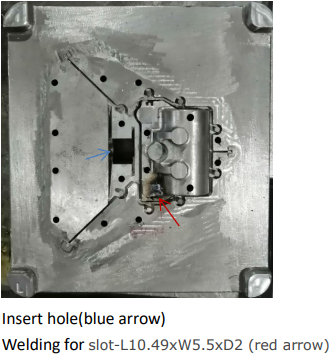

Insert forms the added wall, steel marked by red line is removed by wire-cut

There is a seal-off area around the 2.0 hole to prevent burrs happening from plastic overflow, the maximum height of wall can be made at 14.5mm, not 14.7mm as drawing. And, in case the distance between top surface of the wall and the 2.0 hole is shorter than 0.5, the steel at this distance is easily removed by the back and forth move of 2.0 steel rod during production process.

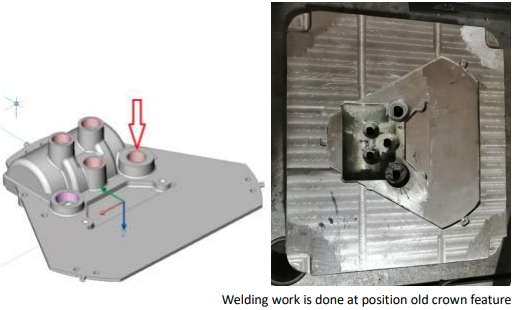

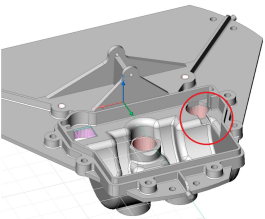

3.) Reduce plastic to make a slot(L10.49xW5.5xD2) at back side of newly required pg7 thread hole at old crown feature

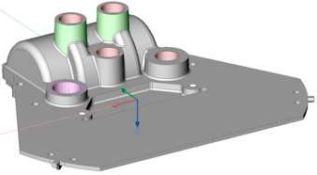

4.)Offset outside walls(green) of last time added 2 pg7 thread holes by 0.8mm(diameter increased by 1.6mm)

5.)Increase 2pcs pg7 thread length by 3mm more