*Part name: LoRain sealing part v5

*In material: Solid silicone rubber shore A 10

*Natural color: translucent (half transparent)

*Production process: compression molding

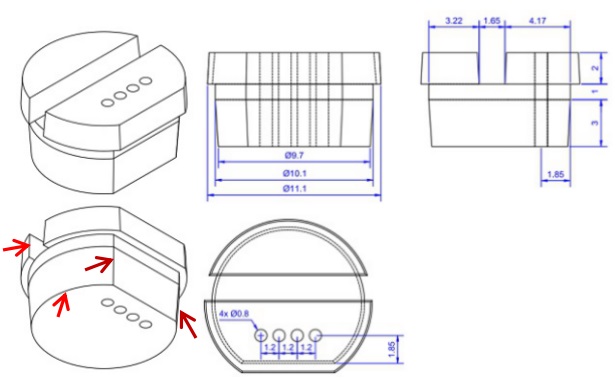

*In design of compression molding tooling, sharp or right-angle corners(red arrows indicated) of part design are rounded with R0.5. Considering shrinkage rate of special silicone rubber is 3%, most possibly, these corner features would be there as originally desired after part is molded. Incidentally, the EDM machining work in tooling, which is needed to get these corners, are avoided. -Mar.27th, 2020

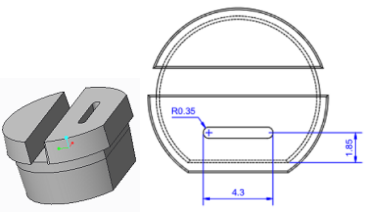

*The milling cutter, which made the pins shaping 4pcs ø0.8 hole, has 8° slope. The 0.4mm distance between 4pcs holes can’t practically exist after sealing part is molded. Therefore, the area of the 4pcs ø0.8 holes is changed to a 0.7x4.3x6mm narrow slot, with smaller and narrower whole slot size than previous 4 holes design to achieve better sealing effect. -Apr. 8th, 2020

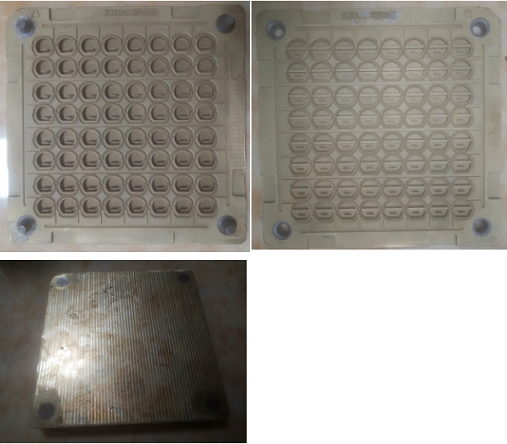

*Apr.23rd, 2020 part samples from tooling test