Above photo was taken on 8th Feb. 2018

*Part name: Stand for NPK shaker project

*Color: milky white

*Production method: bending PC(Polycarbonate) plastic plate (in 3mm thickness, porcelin white color)

milling slot; drilling holes

*Bending angles required for this part: 15° and 90°

Bending angle tolerance +/-10°

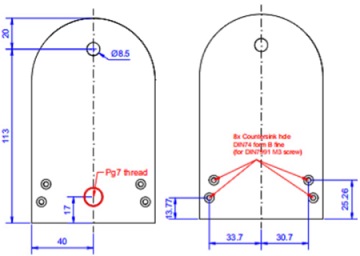

* 28th Mar., 2018: change thickness from 3mm to 5mm resulting in modified overall size and bending positions, change Dia. of two holes from 8mm to 8.5mm, increase size of 'rectangular opening' by 2mm, change 4 holes to countersink for M3 screws.

(Initial sample size:140*80*133mm 28th Apr. 2018)

(Initial sample size:140*80*133mm 28th Apr. 2018)

Dimensional tolerance: +/-0.2mm, actual color for 101pcs 5th May, 2018, milky white

*MobiLab_shaker_stand v5 (18th, Mar., 2019):

a. an addintonal Pg7 thread hole is needed.(after drilling thread hole by screw tap, threaded through hole do not need check thread situation, threaded blind hole need checking)

b. all 8 countersink holes suit to DIN7991 M3 screw head specification.

c. added symmetry on the drawing and avoided unnecessarily complex dimensions.